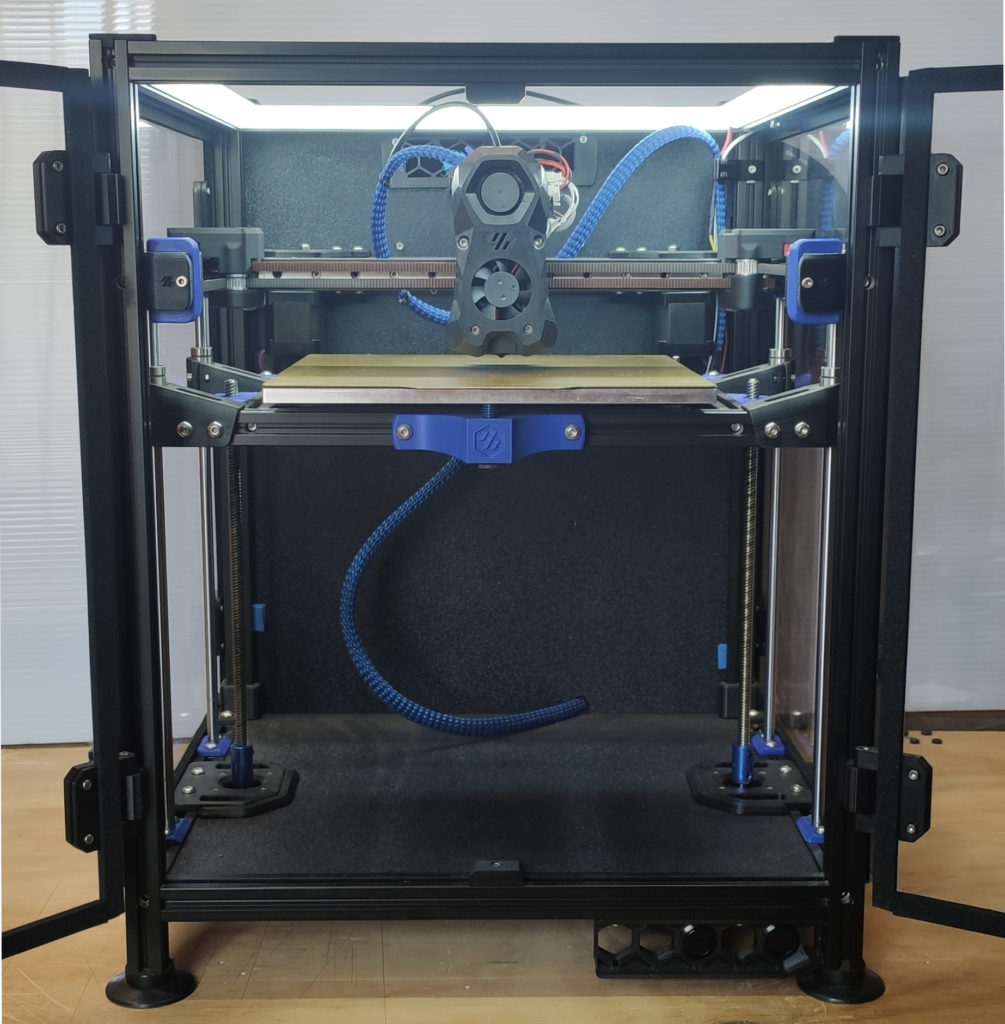

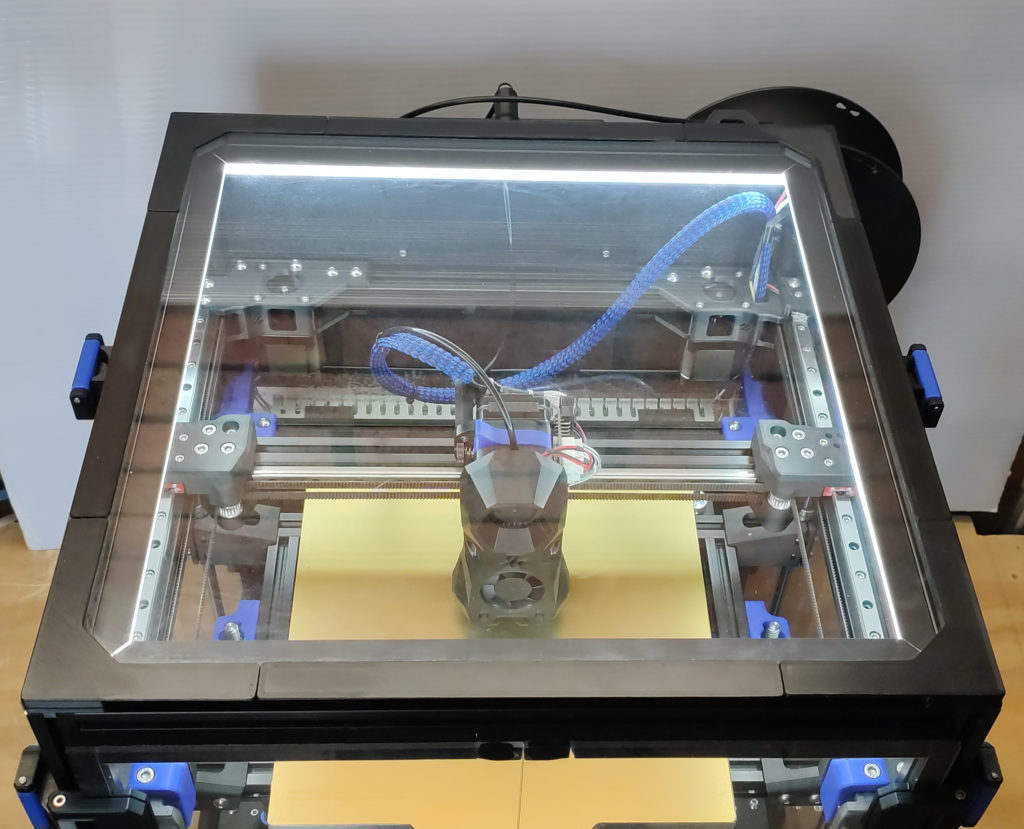

Voron 1.8

The world of desktop 3D printing and additive manufacturing in general is still young and constantly evolving. Commercial desktop 3D printers are quickly becoming obsolete or difficult to update due to their proprietary design.

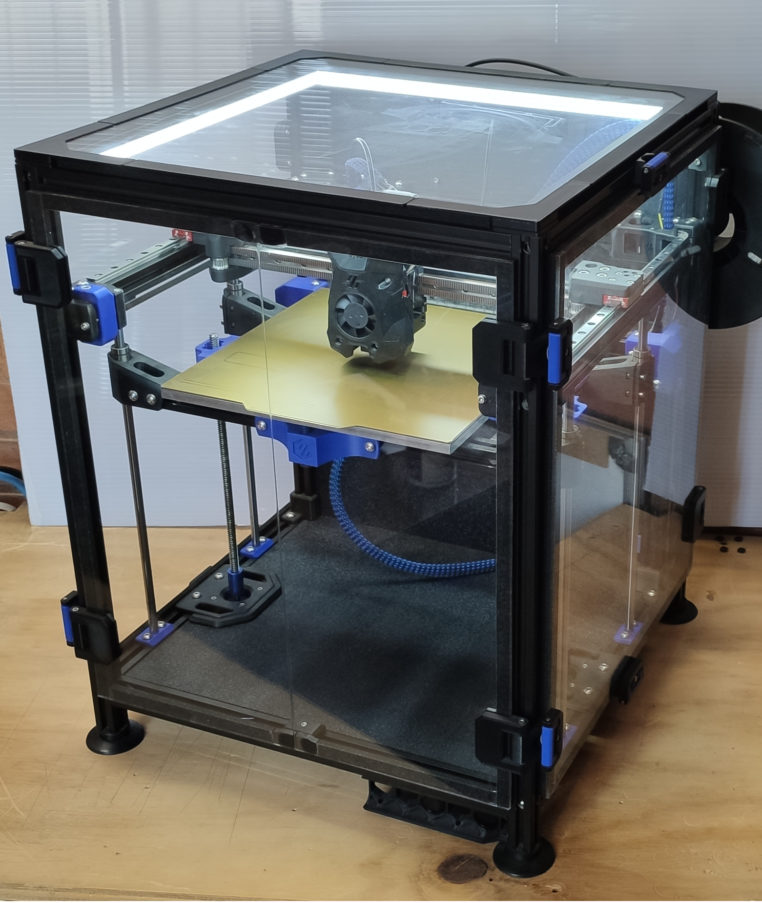

We were impressed by the quality and thoroughness of the design of the Voron 1.8 open source 3D printer, its knowledgeable community and the many improvements available and to come.

All parts have been printed in ABS by us and following the developers’ instructions.

Print volume : 250x250x200mm

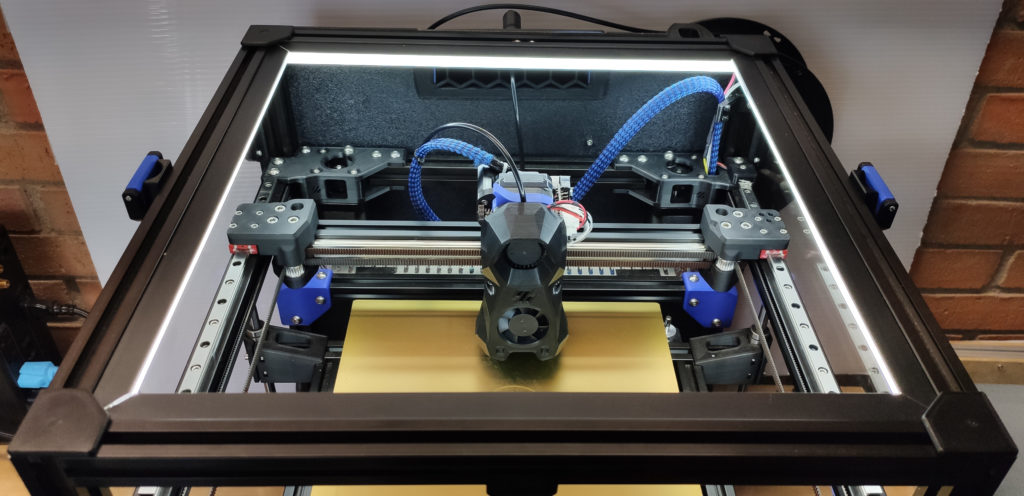

CoreXY kinematics:

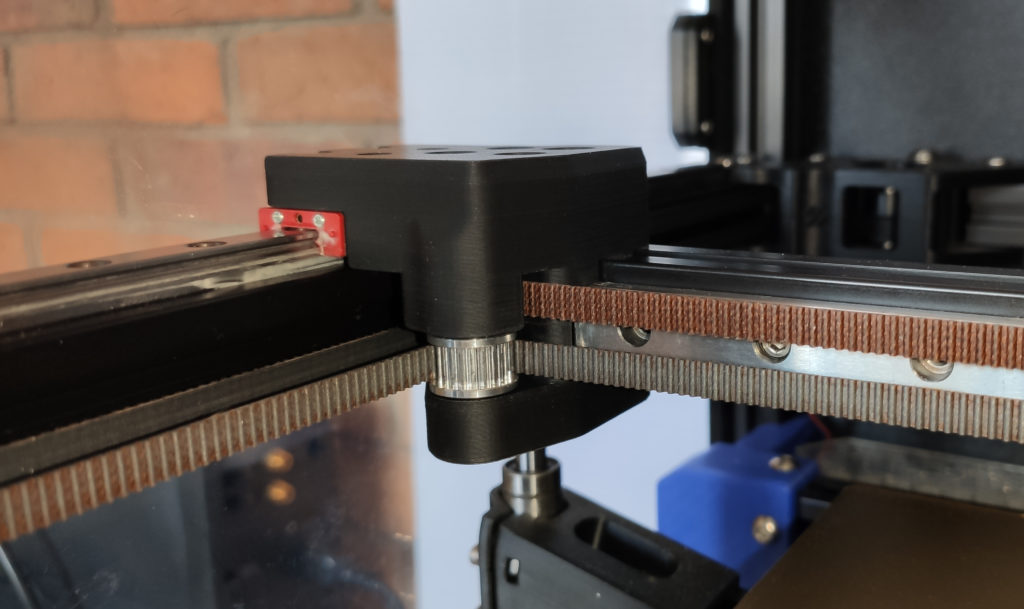

The CoreXY kinematics simultaneously uses 2 motors (A and B) and a specific belt path to this kinematics to transmit its movements in X and Y. This considerably reduces the the print head inertia, resulting in the possibility of high travel speeds (mm/s), acceleration (mm/s²) and jerk (mm/s³) while maintaining excellent print quality.

Frame and motion :

The frame is made with 2020 aluminum profiles.

The translation of the X axis is provided by an MGN12H carriage mounted on its rail, the Y axis is mounted on 2 MGN9 rails.

The Z buildplate is guided by four Ø8mm smooth rods and 2 trapezoidal leadscrews.

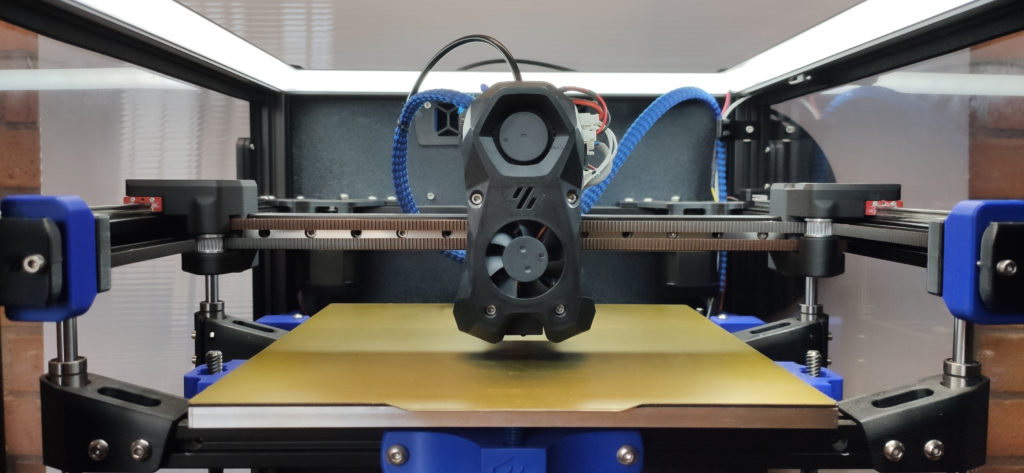

Print head :

The nema 17 motor located at the rear of the head feeds the filament directly into the heat block via a dual gear extruder and offers optimal control of the material flow at the nozzle outlet. It is equipped with an inductive probe sensor to facilitate leveling of the print bed. The Stealthburner cool the heatsink with an axial fan 4010 while a radial fan 5015 cools the printed parts.

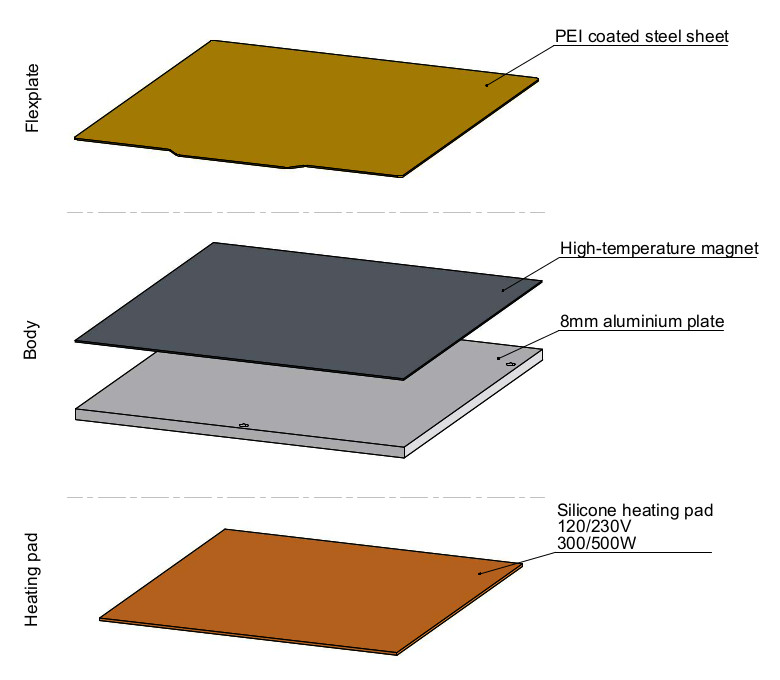

The buildplate can be separate in 3 parts :

The body is an 8 mm thick rectified aluminum plate with a high temperature magnetic sheet stuck on it. The thickness of the aluminium plate minimise the thermal deflection up to 110° C and ensure a flatness of the surface.

The steel sheet is thin enough to be flexible. It is coated with polyetherimide (PEI) on both side and can be smooth or textured. PEI flexplate ensure an excellent adhesion with PLA, PET-G, ABS and ASA but is not recommended for TPU. When a print is complete the flexplate is manually removed and bent to take off the parts effortlessly and harmlessly.

The silicone heating pad is glued below the body, it ensures an uniform heating of the body and the flexible plate. The silicone is supplied with 120V or 230V through an SSR and protected by a fuse. Heating temperature is controlled by a sensor connected to the printer’s motherboard.

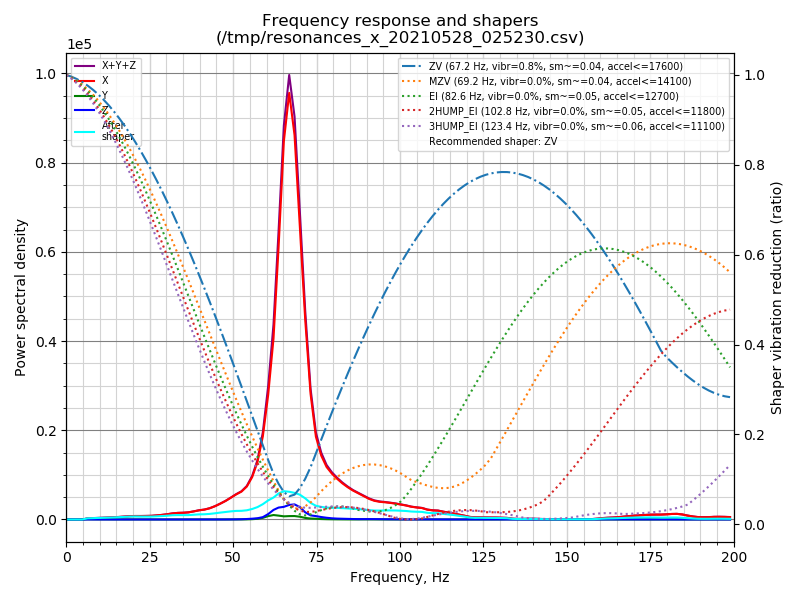

Resonance measurement (Input Shaping):

Input Shaping is an open loop control technique for reducing vibration in computer controlled machines. The method works by creating a control signal that cancels its own vibration. Installing an accelerometer on the printhead provides measurements and suggested corrections for printer acceleration.

More information about Input Shaping.

Mods and developments on the Voron 1.8:

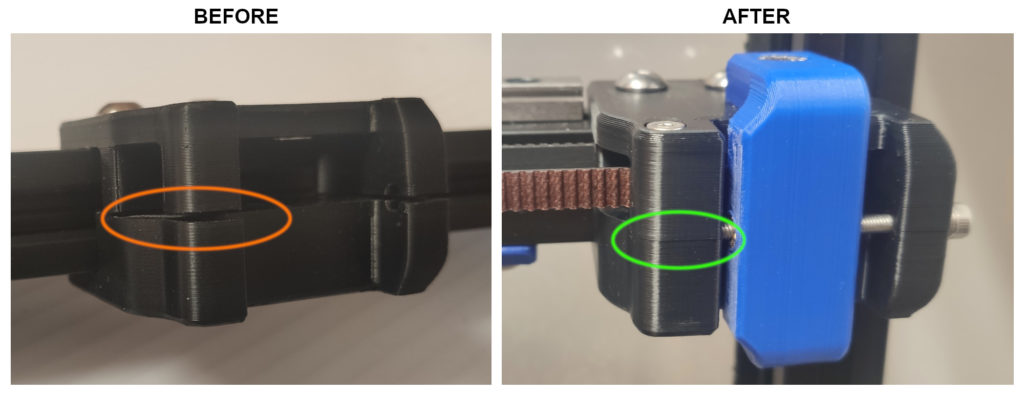

Improvement of the front idlers A and B.

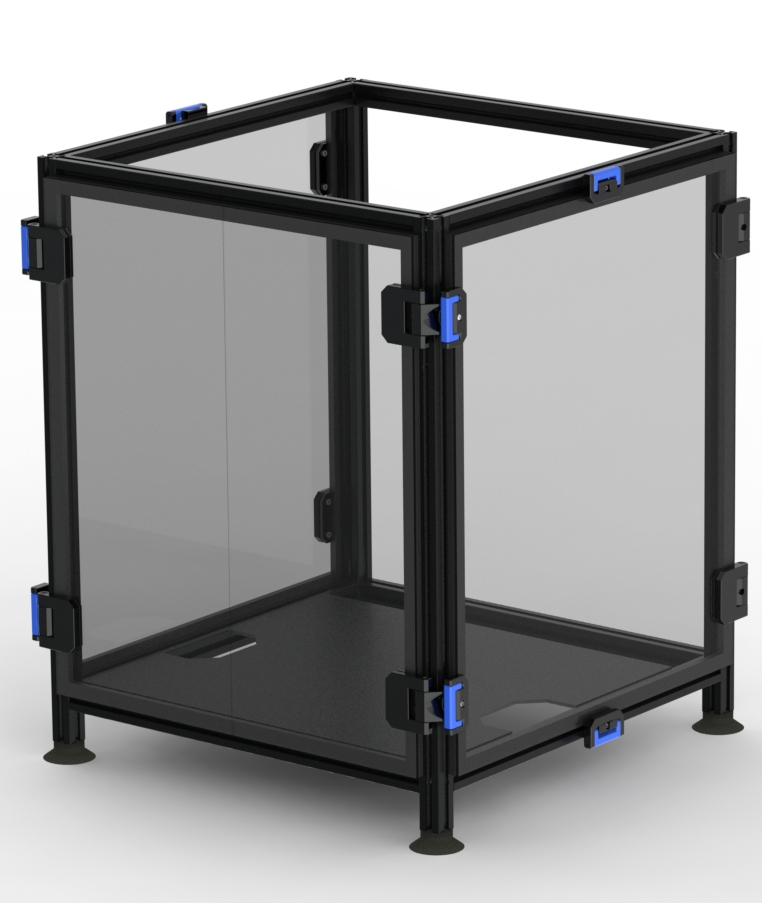

Enclosure : removable lateral panels and front doors + toggle latch.

Added a temperature chamber sensor and an exhaust fan with activated charcoal + HEPA filter.

Led strip mount and diffusers.

Modification of the length of the lower skirt and integration of Ø19mm push button housing.

Replacement of the 2 linear guides MGN9 of the X axis by a single rail MGN12H.

Safety mount for the buildplate cables.

More information on the official website: vorondesign